CNC Roll Form C/Z

We do your CNC Roll Form C/Z work faster.

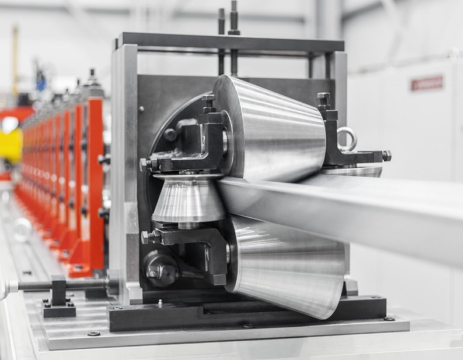

With our rollform machines, we can easily manufacture open and closed (clamped profile - welded profile - perforated profile - non-perforated profile) profiles within high surface quality and low dimensional tolerances, at high production volumes, using low labor force and combining many processes. Get products with perfect and fine details.

CNC Roll Form C/Z How is the process done?

The material is usually added in sheet form or fed continuously from a coil. The next section, station rollers, is where the stations where roll formation takes place, where the metal sheet forming process begins. The metal is shaped as it moves between rollers on roll form lines throughout the process. The next part of the sheet metal forming machine is the shearing press, where the metal is cut to a predetermined length. The final section is the manually controlled exit station, where finished products are transferred from the roll form machine to a roller conveyor or table.

To get detailed information and price offer