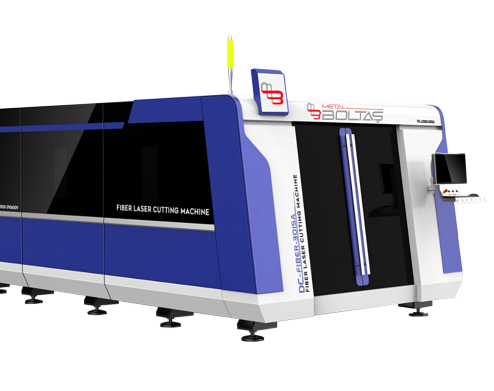

Fiber Laser

Closed Case Double Table 15KW 2000X6000

FIBER LASER CUTTING MACHINE

Laser Cutting is the process of processing mild steel using a laser beam using fiber-optic cables and a cutting head. The cutting beam is focused by a lens and heats the surface to be cut to a temperature well above the ignition point, resulting in a molten metal puddle. A hole is created by injecting auxiliary gas (Air - oxygen - Nitrogen, etc.) into the molten metal deposit and removing the metal deposit there.

Oxidation reaction When the laser beam is moved, the kinetic energy of the injected auxiliary gas and the oxidation reaction with the cutting gas repeatedly remove the material in depth, direction and shape the part through forming a continuous cutting groove.

Oxidation reaction When the laser beam is moved, the kinetic energy of the injected auxiliary gas and the oxidation reaction with the cutting gas repeatedly remove the material in depth, direction and shape the part through forming a continuous cutting groove.

> New closed design double tray,

> Quick change edge cutting,

> Small spacing,

> Smooth surface

> Large production capacity

> New closed design double tray,

> Quick change edge cutting,

> Small spacing,

> Smooth surface

> Large production capacity

MACHINE PARAMETERS

| LASER POWER | 15000W | ||||||||||||||||||||||||||||

| LASER WAVELENGTH | 1064nm | ||||||||||||||||||||||||||||

| LASER BEAM DIAMETER | 150 μm – 410 μm | ||||||||||||||||||||||||||||

| LASER BEAM QUALITY | <0.373 mrad | ||||||||||||||||||||||||||||

| X-AXIS MOTION | 2030 | ||||||||||||||||||||||||||||

| Y-AXIS MOTION | 6080 | ||||||||||||||||||||||||||||

| Z-AXIS MOVEMENT | 400 | ||||||||||||||||||||||||||||

| MACHINE ACCELERATION | 1.5G | ||||||||||||||||||||||||||||

| X/Y AXIS POSITIONING | ≤±0.03mm/m | ||||||||||||||||||||||||||||

| X/Y AXIS REPEATABILITY | ≤±0.02 mm/m | ||||||||||||||||||||||||||||

| HIGHEST SPEED | MACHINE PARAMETERS

|